Our Processes

Turnkey Beverage Packaging

From initial concepts, through manufacturing, to delivery, our team will help manage your entire beverage carrier project from start to finish.

Structural Design

WP Beverage Carriers offers a wide array of beverage carrier styles that offer functional, durable, and visually appealing solutions. Whether you’re packing in cans or bottles, we offer a selection of stock carriers in a variety of sizes.

Looking for a custom solution? Our Structural Designers will collaborate with you to understand your specific brand, product and fulfillment requirements, and market positioning to develop a unique carton structure for you.

Graphic Design

Wynalda’s graphic design services are tailored to elevate your brand presence and help your product stand out on the shelves. Our team of experienced designers works closely with you to understand your brand identity, target audience, and specific requirements. Whether you need vibrant, eye-catching designs or elegant, sophisticated packaging, we have the expertise to bring your vision to life.

Our designs are optimized for printing, ensuring that the final product is crisp, clear, and true to your vision. 3D renderings and digitally printed mock-ups are available to help you visualize the final product before it goes to production.

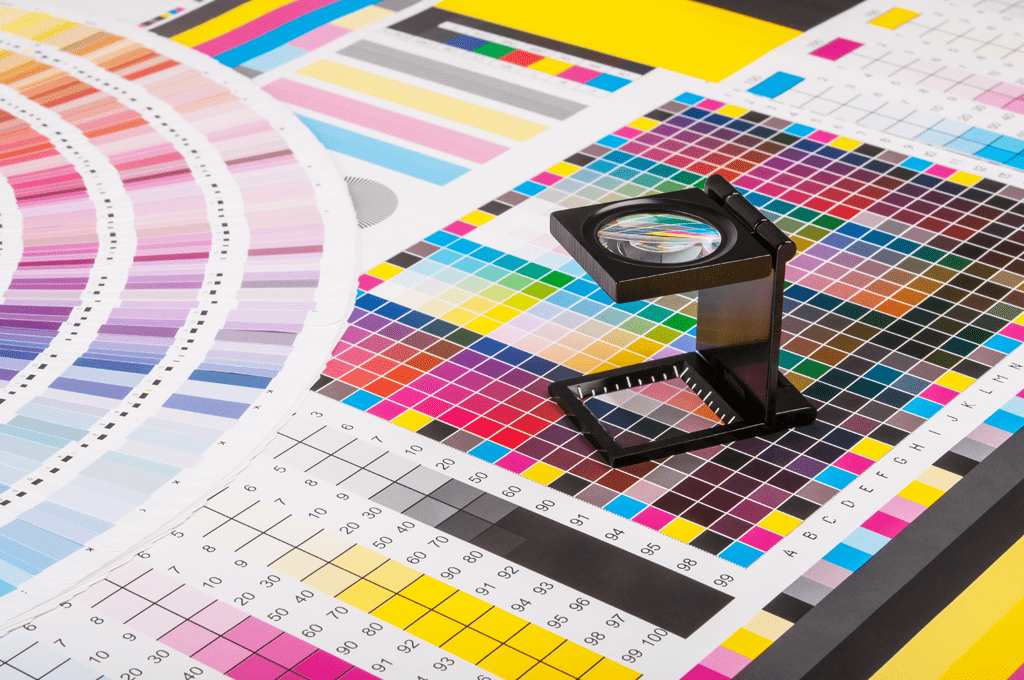

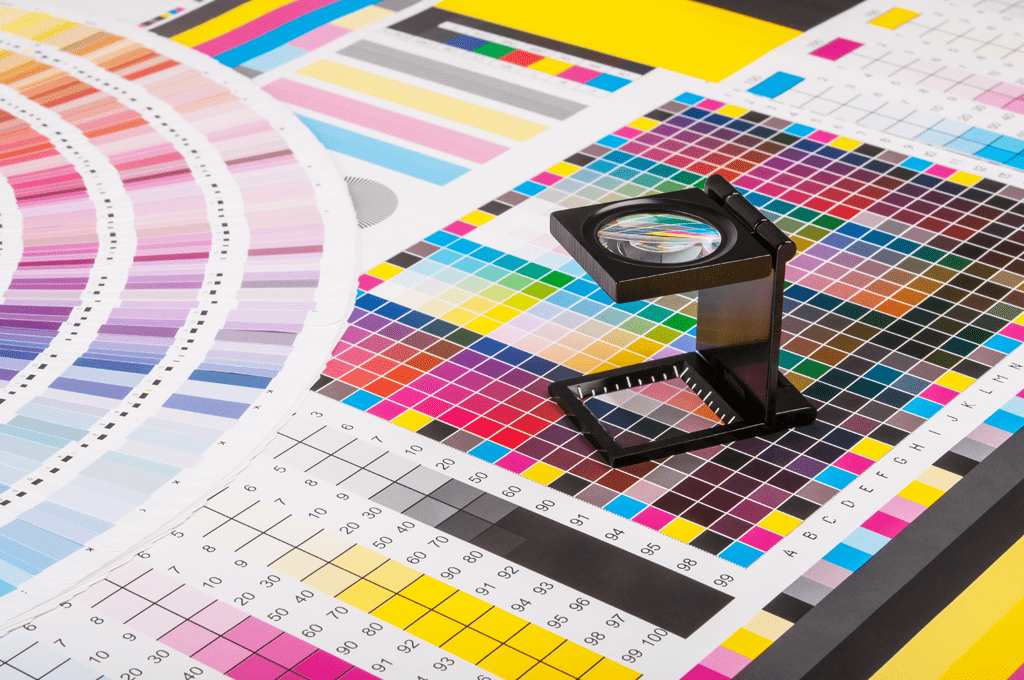

Pre-Press

Before beverage carriers are manufactured, our Pre-Press Team performs several key steps:

- File Preparation: ensuring the digital files received are correctly formatted and suitable for printing.

- Image Manipulation: adjusting images, text, and color for optimal print quality.

- Proofing: outputting both digital and hard copy proofs to ensure color accuracy and an opportunity to check for and correct any errors within the artwork.

- Quality Control: conducting checks to ensure everything meets Wynalda’s required standards before printing.

- Plate Production: creating the print plates used on our offset printing presses.

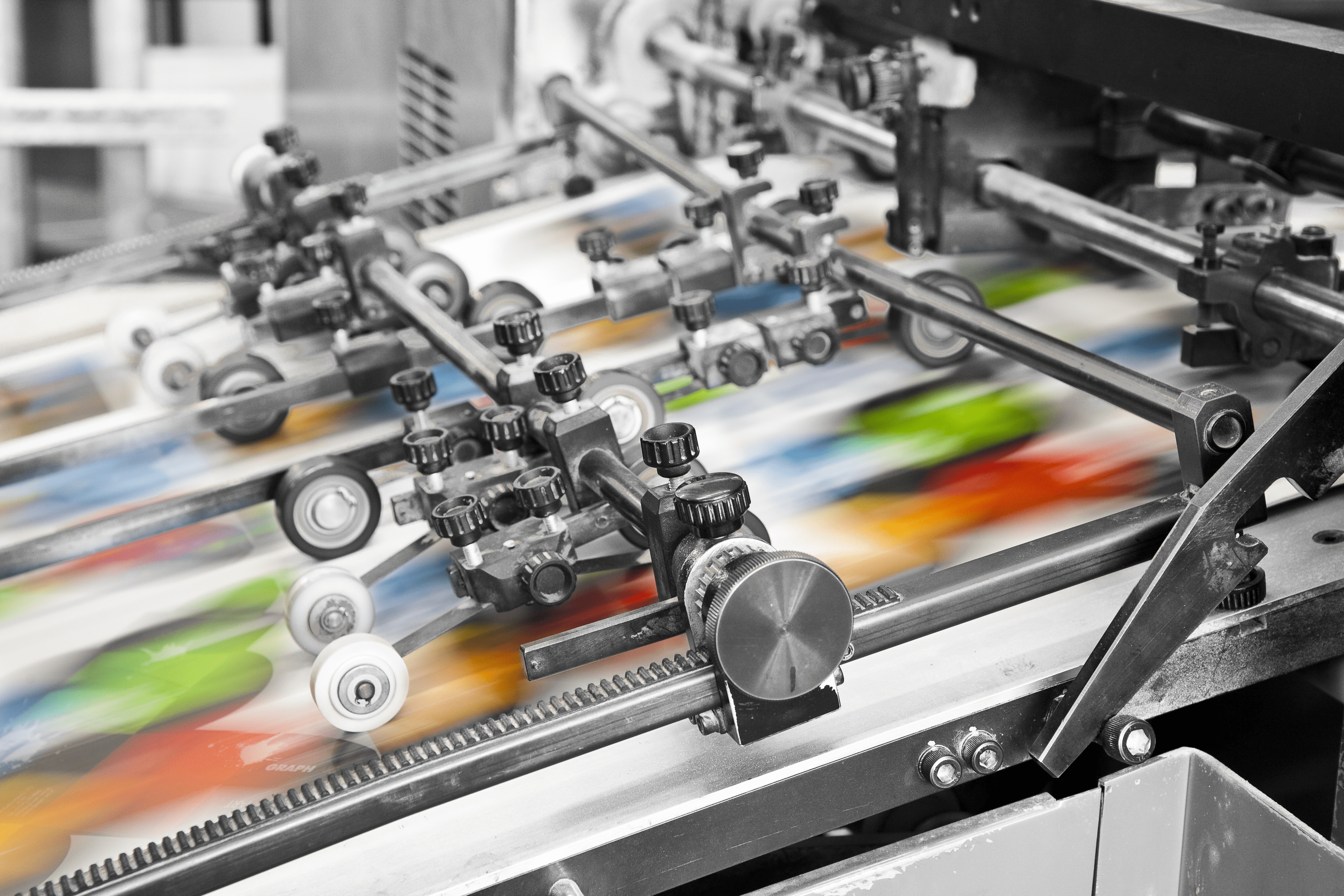

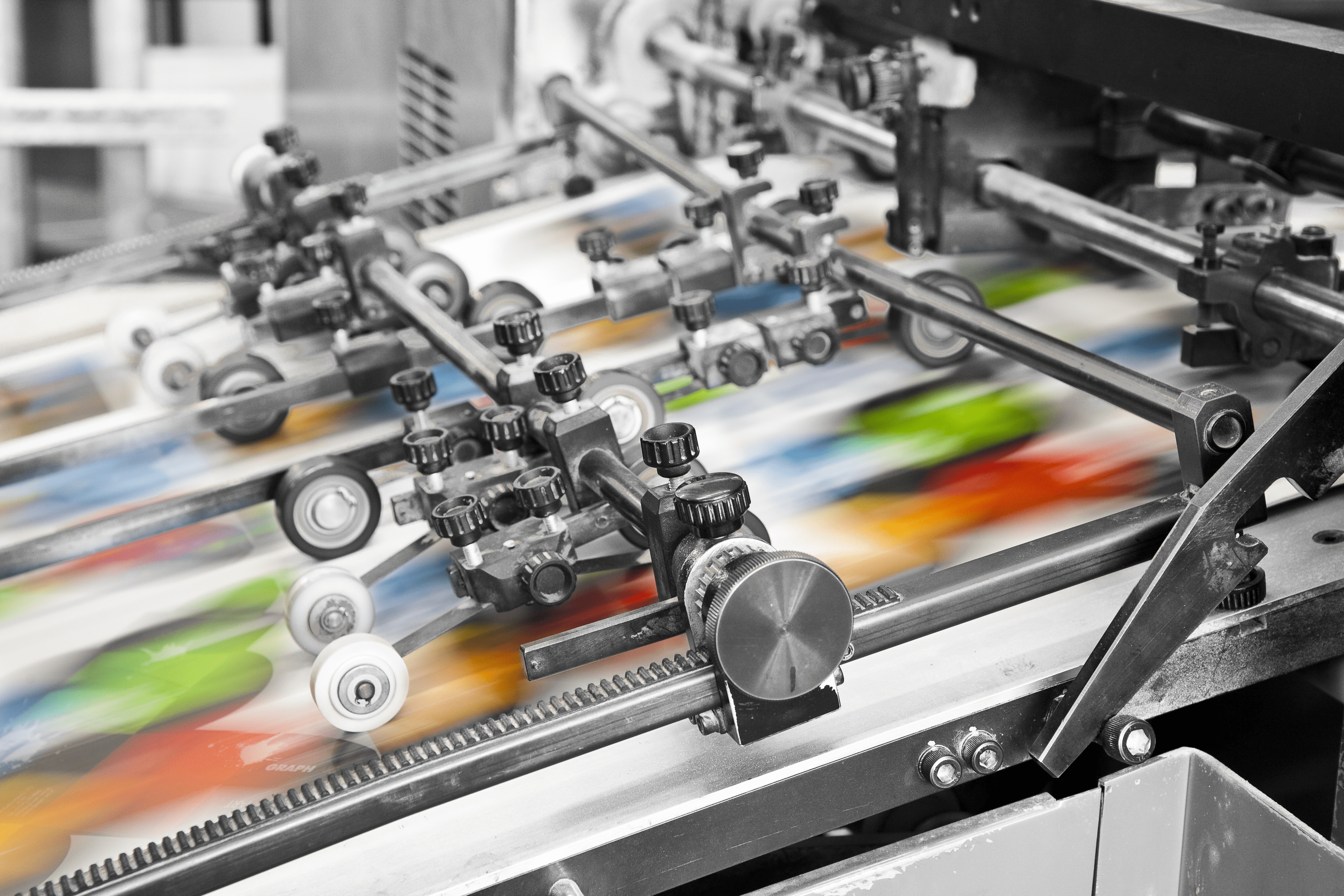

Printing

WP Beverage Carriers has uniquely configured printing presses to meet the specific demands of our customers. Our presses ensure high image quality and color consistency, and allow for the application of multiple coatings and spot colors to help your brand stand-out from the competition.

Printing beyond the standard 4-color process of CYMK, incorporating custom matched colors is a great way to ensure greater color consistency across different print productions, enhance the visual appeal of the beverage carriers, and establish a brand identity.

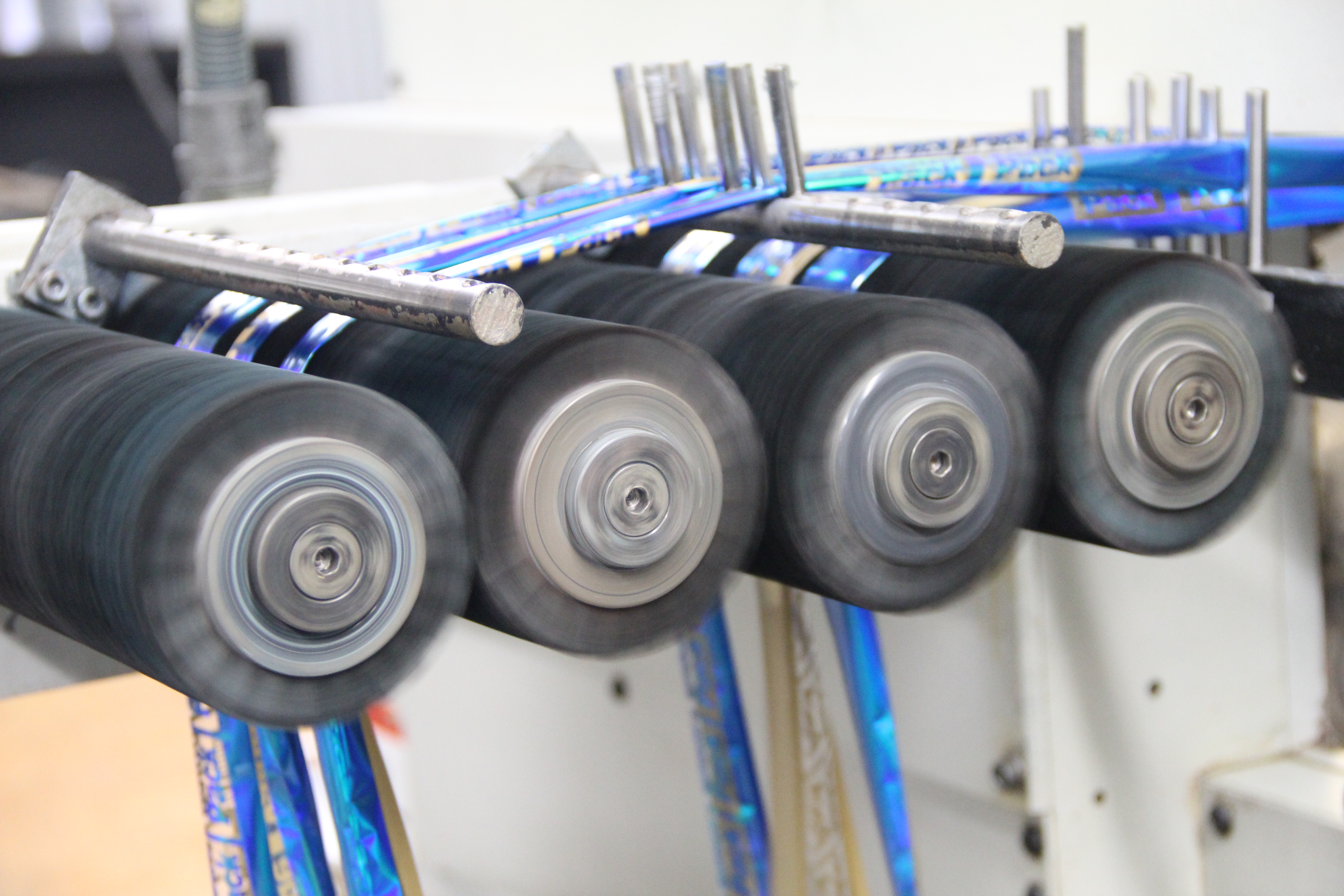

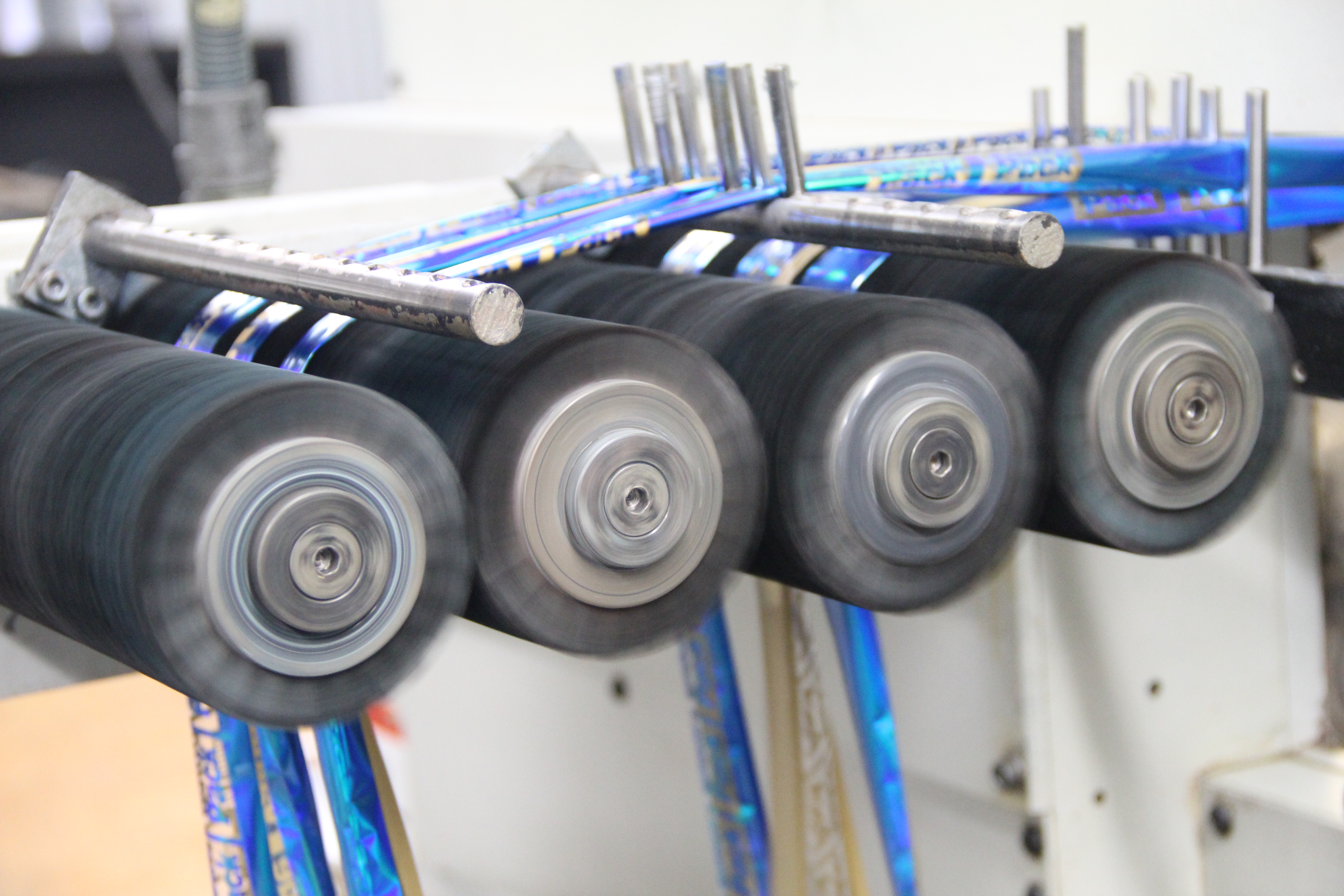

Special Treatments

Beyond printing, incorporating additional embellishments can enhance the visual appeal and perceived value of the product and packaging. Special treatments may be used singularly or in combination with each other to create spectacular designs.

Additional treatments may include:

- Hot Foil Stamping & Cold Foil Printing

- Embossing & Debossing

- Custom Inks & Coatings

Structural Design

WP Beverage Carriers offers a wide array of beverage carrier styles that offer functional, durable, and visually appealing solutions. Whether you’re packing in cans or bottles, we offer a selection of stock carriers in a variety of sizes.

Looking for a custom solution? Our Structural Designers will collaborate with you to understand your specific brand, product and fulfillment requirements, and market positioning to develop a unique carton structure for you.

Graphic Design

Wynalda’s graphic design services are tailored to elevate your brand presence and help your product stand out on the shelves. Our team of experienced designers works closely with you to understand your brand identity, target audience, and specific requirements. Whether you need vibrant, eye-catching designs or elegant, sophisticated packaging, we have the expertise to bring your vision to life.

Our designs are optimized for printing, ensuring that the final product is crisp, clear, and true to your vision. 3D renderings and digitally printed mock-ups are available to help you visualize the final product before it goes to production.

Pre-Press

Before beverage carriers are manufactured, our Pre-Press Team performs several key steps:

- File Preparation: ensuring the digital files received are correctly formatted and suitable for printing.

- Image Manipulation: adjusting images, text, and color for optimal print quality.

- Proofing: outputting both digital and hard copy proofs to ensure color accuracy and an opportunity to check for and correct any errors within the artwork.

- Quality Control: conducting checks to ensure everything meets Wynalda’s required standards before printing.

- Plate Production: creating the print plates used on our offset printing presses.

Printing

WP Beverage Carriers has uniquely configured printing presses to meet the specific demands of our customers. Our presses ensure high image quality and color consistency, and allow for the application of multiple coatings and spot colors to help your brand stand-out from the competition.

Printing beyond the standard 4-color process of CYMK, incorporating custom matched colors is a great way to ensure greater color consistency across different print productions, enhance the visual appeal of the beverage carriers, and establish a brand identity.

Special Treatments

Beyond printing, incorporating additional embellishments can enhance the visual appeal and perceived value of the product and packaging. Special treatments may be used singularly or in combination with each other to create spectacular designs.

Additional treatments may include:

- Hot Foil Stamping & Cold Foil Printing

- Embossing & Debossing

- Custom Inks & Coatings

Inventory Management

Depending on the scope of your beverage carrier needs, WP Beverage Carriers offers customizable Vendor Managed Inventory (VMI) programs. Implementing a VMI program into your packaging program may allow for:

- Cost savings: ordering larger volumes in single print productions

- On-demand shipping: inventory items available for shipment within 24-48 hours

- Scheduled inventory releases: streamlining demands on supply chain managers

- Available inventory to meet unforecasted needs

Sustainability

WP Beverage Carriers fully realizes the importance of a healthy environment and that every decision made either directly or indirectly impacts the world around us. Below are a few ways we are committed to offering eco-friendly products and services:

- Eco-friendly inks and coatings

- Sustainably sourced raw materials

- Recyclable or biodegradable paperboards

- 100% collection and recycling of scrap and trimmings within our manufacturing facilities

Combination Print Runs

Combination print runs allow us to offer lower prices for breweries with smaller run volumes, while our bi-monthly schedule offers a consistent and dependable production timeline.

See deadlines for our next combination print run.

Request a Quote

. . .Let us know what kind of job you need run and we'll get back to you as soon as possible!